Hydraulic filter – basic types and parameters

A significant proportion of construction machinery failures are caused by improper or insufficient operation hydraulic filter, responsible for filtering oils and removing harmful substances, and the efficiency of the device depends on its quality. Depending on the type and location, hydraulic oil filters they perform different functions and are characterized by different parameters. What is worth knowing about them?

What is a hydraulic filter and what are its functions?

An essential role hydraulic filters is to remove all types of contaminants from the working fluid - most often oil. Modern, highly sensitive hydraulic filters effectively filter both solid contaminants and chemical substances that could get into machine parts.

Hydraulic oil filters successfully stop impurities such as:

- chemical compounds, including dangerous acids;

- water that may interfere with the operation of the hydraulic system;

- metal filings, sand and other industrial dust;

- organic substances, including microbes and pathogens.

Filtration in the machine's hydraulic system can take place according to two schemes - mechanical and force. Mechanical type of filtration uses hydraulic oil filter inserts, which retains all impurities larger than the channels that let the liquid through. The size of these channels is selected depending on the types of contaminants to be removed and the density of the liquid in the system. This way most often filter inserts mechanical ones are made of cellulose, polypropylene non-woven fabric or metal sieve.

Power filtration, on the other hand, uses physical forces - most often gravity or centrifugal force, less often magnetic force. This type of filtration usually protects the machine against contamination from the outside - the filter is therefore located outside the machine's hydraulic circuit.

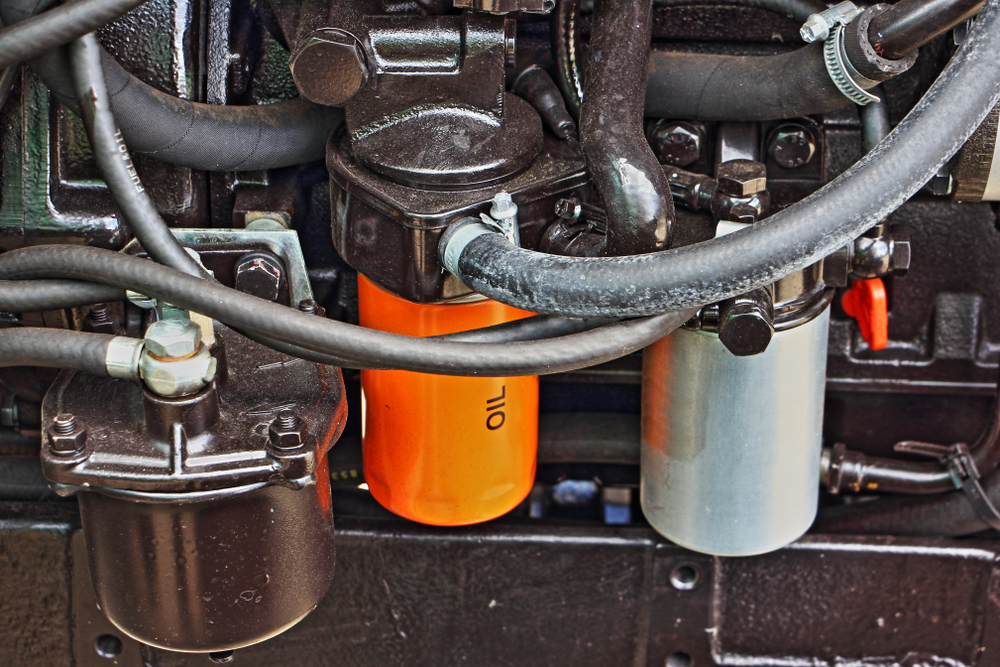

Types of hydraulic filters

The type of filters in the hydraulic system depends primarily on the type of the system itself - closed or open. In addition, the sensitivity of machine components to contamination, the level of dust in the workplace and the operating pressure in the hydraulic system are also important.

On this basis, we can distinguish several basic types hydraulic filters. What are the most important functions of each?

- Hydraulic suction filter – is placed in the tank on the suction line connected to the system pump. Hydraulic oil suction filter cleanses the liquid before it enters the pump and then is introduced to other elements of the hydraulic system. The filter element is usually a metal mesh.

- Hydraulic filter low-pressure - it is installed just after the pump outlet with a pressure of no more than several dozen bars.

- Hydraulic filter high pressure – this filter is used to filter liquids with a pressure exceeding 100 bar.

- Inlet filter – this is a type of external filter. It closes the system and protects against external contaminants from entering the system. It is usually located on the surface of the tank and pre-filters the liquids with which the tank is filled. Infusion hydraulic filters are equipped with a vent that allows the liquid to evaporate freely, but protects against contamination from entering the system.

- Hydraulic return filter – as the name suggests, this filter is designed to clean hydraulic oil that has already passed through the entire system and returns to the tank. Characteristic return hydraulic filters most often there is high accuracy.

Many of these filters are also equipped with additional accessories. The most common use is the contamination indicator, which provides information about the degree of filter wear and the pressure drop across the filter. Such a device allows you to constantly monitor the condition filter insert and avoid not only damage to the system, but also unnecessary filter replacement.

Basic parameters of the hydraulic oil filter. What to pay attention to when purchasing?

Basic parameters hydraulic filter they determine features such as the degree of filtration and its effectiveness, as well as hydraulic resistance. What do these parameters mean and how do they affect the functioning of the machine?

Filtration coefficient

The degree/coefficient of filtration determines how much contaminants it can filter out hydraulic filter. It's not about what pollutants will or won't be retained. The key is whether the filter works efficiently when the liquid is heavily contaminated. The filtration coefficient will tell you what degree of contamination of the hydraulic oil will not cause disruptions in the operation of the machine. The higher this indicator, the more efficient the filter works.

Filtration efficiency

Similar information is provided by the degree of effectiveness hydraulic filter. It tells us what percentage of particles of a specific size are retained in the filtration process. It is not how much contaminated liquid it can filter, but how many particles will further penetrate the system, regardless of the degree of contamination of the liquid.

Hydraulic resistance

A critical parameter for the functioning of the machine is the hydraulic resistance indicator. You must know that the liquid has less pressure after flowing through the filter - if the resistance coefficient is too high or too small, the liquid may damage the elements of the hydraulic system or significantly reduce its efficiency.

Of course, we must not forget that hydraulic filter must be fully adapted to the system elements. Before purchasing, also consider parameters such as:

- external dimensions of the filter – diameter and length;

- seal diameter;

- diameter and type of thread;

- number of valves.

Also remember that even the best quality hydraulic filters have a limited lifespan. Regular inspections of all hydraulic system components and replacement of filters that do not operate at optimal efficiency are also extremely important. Thanks to this, you will be able to avoid equipment failure - a faulty filter operation affects not only the efficiency of the hydraulic system itself, but also the remaining components of the machine.

You are looking for high quality hydraulic filters? Choose original spare parts that will extend the life of the machine, facilitate its operation and ensure maximum operational safety. At GIZO you will find components from leading manufacturers, including: Manitou hydraulic filters.