Proper selection of the electric lift coil

Electric coil is one of the most important elements of electric machines. Even though it serves a critical function for lifters, protecting them against harmful changes in current, its construction is simple. It is also not an expensive or unavailable component. Appropriate type of electric coil you can find it in almost every spare parts store for construction equipment. Therefore, it is worth ensuring that it is always in the best possible condition and replacing it as soon as signs of wear begin to be visible. How to check an electric coil? And how to choose the right one?

What are electric coils and what functions do they perform in the lift?

Electric coil it is a component of many parts of electrical devices. Due to the fact that it has high resistance (resistance) to undesirable current changes, it is also called an alternating current resistor. It is used in virtually every device, most often in drive systems.

Basic function electric coil is to filter the voltage and also to collect the magnetic field energy. The principle of operation of coils is based on the phenomenon of inductance or self-induction. What is it about? It is a passive element, i.e. one that does not work on its own, but only when current flows through it. In such a situation, a magnetic field is generated around the wire wound on the core. If there is a change in the current, the so-called reverse voltage, which will force current to flow in the opposite direction. Thanks to this, the change in current will not affect other elements of electrical devices and will not damage them.

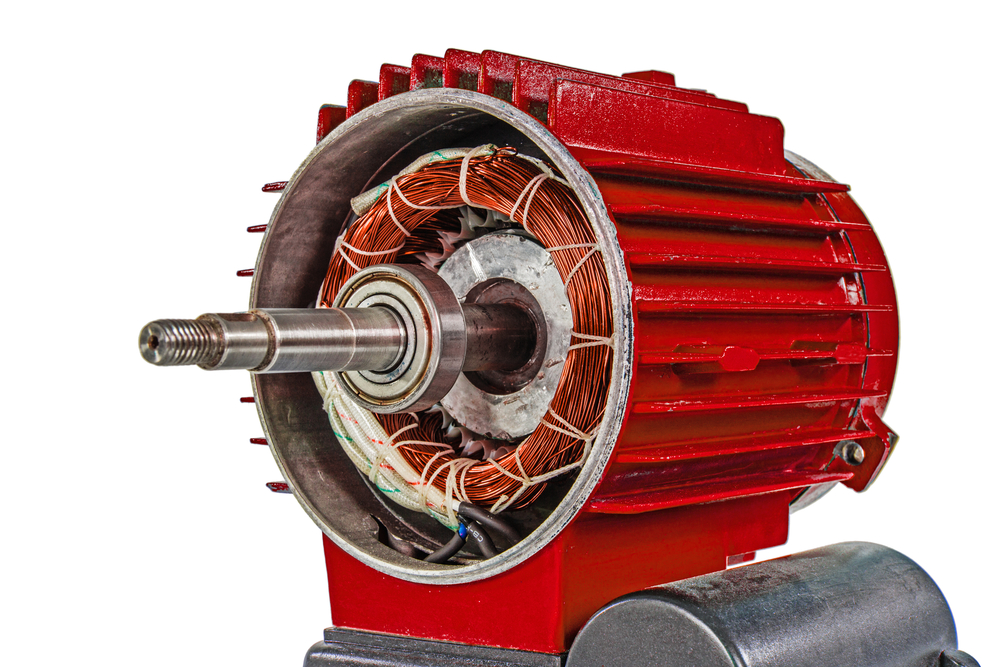

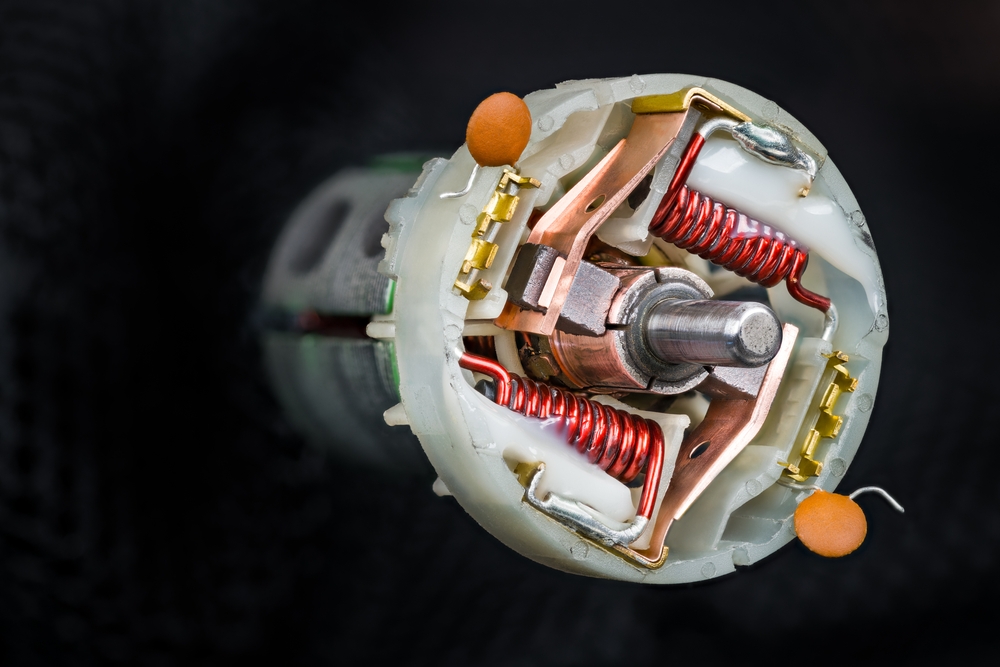

Types and structure of electric coil

Construction of an electric coil is very simple. It consists of just two elements: coils of copper wire and a core made of various materials, depending on the functions the coil is to perform. The properties of the coil also depend on the thickness of the wire and the number of windings.

Coils are differentiated primarily by the number of turns and the type of core used in them. This way you can distinguish:

- air coils – they do not contain a core;

- iron core induction coils, also called ferromagnetic coils;

- coils with a ferrite core;

- coils with a toroidal core;

- coils wound on a spool;

- multilayer inductors;

- thin film induction coils.

The most important parameter determining properties electric coil is the inductance expressed in units called Henry. The higher the value of this parameter, the more effectively the coil works and it can respond to a greater range of current changes.

How to choose an electric coil?

Various types of coils are available, depending on the component's application, design and rating. When it comes to coils for elevators, first of all, you should pay attention to their functions and choose a coil that is adapted to work with a specific component of the machine: it has the same type of plug or hole diameter.

Available include:

- gas solenoid valve coil;

- hydraulic distributor coil;

- emergency lowering solenoid valve coil;

- engine extinguishing coil;

- gas coil.

Remember that you always have to choose electric coil with the same ratings as the factory-installed part. Detailed technical data are usually located on the housing of this component - check them carefully after disassembly. If you are unsure or the data on the manufacturer's sticker is illegible, you can check the device's manual or check the technical parameters of a specific coil at a seller of spare parts for construction machines. Most parts stores also list which models a specific one fits electric coil. This is the surest way to select the right part.

Why should you pay attention to this? If technical parameters electric coil do not correspond to the properties of the machine (e.g. incorrect resistance was selected), device operation disorders may occur, including even lower engine efficiency. In many cases, this results in damage to the coil and other components.

Where to buy electric coils for lifts?

When selecting coils for an electric motor it is also worth paying attention to the quality of the product itself. It is best if the repair uses the coil recommended by the manufacturer - i.e. the original one. Such parts ensure greater efficiency and durability of the device. Moreover, they are covered by a warranty - in the event of another failure, there will be no problem with repairing the equipment and financing it.

However, the use of cheaper substitutes is not recommended, although this is a solution that is successfully used by many service companies. Before replacing the coil yourself, it is worth seeking professional advice and choosing the method that suits you best. However, it is worth being aware of the potential consequences. We recommend using original coils, in accordance with the manufacturer's recommendations.

You need advice on choosing electric coil to the lift? Contact us! Our team of specialists will provide you with comprehensive answers to your questions.